Conceivably a 4 color process print with only 4 screens will cost as much or more than 10 or 12 color job due to the time and effort involved in printing it. In almost all cases spot color bumps are added to the 4 color process seps to help achieve the red, green and neutral gray in order to match the original art. When the graphic has more secondary and tertiary colors than primary colors, it will be very difficult to balance the halftones to achieve the clean greens, browns, purples and neutral grays with no obvious color shift. The fact that we are printing with plastisol (which is basically plastic particles suspended in clear base) does not allow us to achieve the transparency of litho process inks.Ĥ color process printing on t-shirts can cause frustrating production runs by chasing the color, trying to balance the halftones, and eating up hours on press without good results. UltraSeps removes the uncertainly and fear from the t-shirt color separation process providing the end user with the tools to not only generate high-end work, but also a level of confidence of knowing that, yes, I can do this. Specific guidelines dictating substrate, mesh tension, mesh count, line screen, squeegee pressure, squeegee sharpness, and durometer or contact and ink brand are just a few. The largest apparel manufacturers in the world know that time is valuable and its the reason they use our software. Many variables affect the success of the print. Not only do the separations have to be adjusted but the press production crew has a set of very strict parameters to limit the dot gain to the absolute minimum. Now with two distinct separation engines and Sep Studio’s own Print Commander – all art is expertly separated and printed to film with control and confidence.In order to compensate for the dot gain that is inherent with the textile screen printing process, the original RGB file must be converted and adjusted to allow for the excessive gain. If the Channels panel is not visible you can locate it in the Window menu. STEP 2: Click on the Channels panel to reveal the colour channels. The new Spot Process Separation Studio 4™ has 80% more tools and features than the previous version. STEP 1: Open your file in Photoshop, and go to Image then Mode and set the artwork to CMYK. Experience the power of color separation automation with intelligence. in my opinion, management in CMYK is much better in Clip Studio (at least for now.

#CMYK IN SEPARATION STUDIO PLUS#

With Spot Process Separation Studio (SPSS) users get ALL the color accuracy and abilities of Spot Process, PLUS advanced editing tools for targeted color control, an engine power boost for faster processing and screen redraw speeds, an enhanced User Interface for a better workflow, and many other valuable NEW features.ĭon’t waste time fixing client supplied, downloaded, or improperly color managed artwork. What is the best way to do color separation for print out on t-shirt.

#CMYK IN SEPARATION STUDIO SOFTWARE DOWNLOAD#

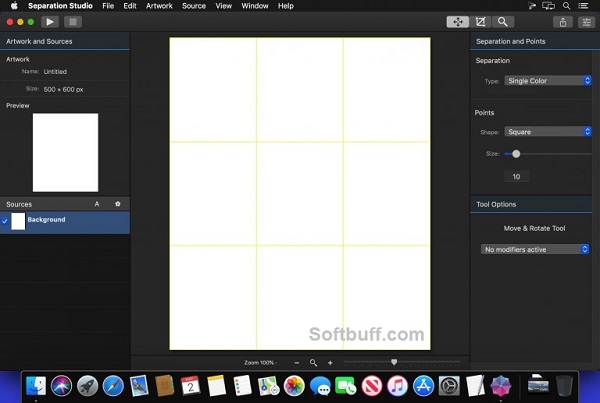

SEPARATION STUDIO SOFTWARE DOWNLOAD GENERATOR Separation Studio is powerful, easy to use color separation and artwork generator tool designed exclusively for Mac. Since its release in 1995 users have been astonished at the quality, speed, ease-of-use, and standards Spot Process delivers to an industry craving a solution to one of the pre-press department’s toughest tasks.Color separating a TONAL image for screen-printing demands color accuracy, a high-quality under-base, highlight top white, and black channel options. Separation Studio is an application that allows you to create single color and cmyk half-tone patterns in vector- based formats. Separation Studio is the latest release of Spot Process, the software that pioneered automated, color image separating.

0 kommentar(er)

0 kommentar(er)